Why Applications Must Address Pain Points To Become A Solution

March 19, 2025

In my career as an innovator and entrepreneur, I’ve seen this time and time again -– applications missing the mark when they fail to fix the pain point that caused the need for developing the solution in the first place.

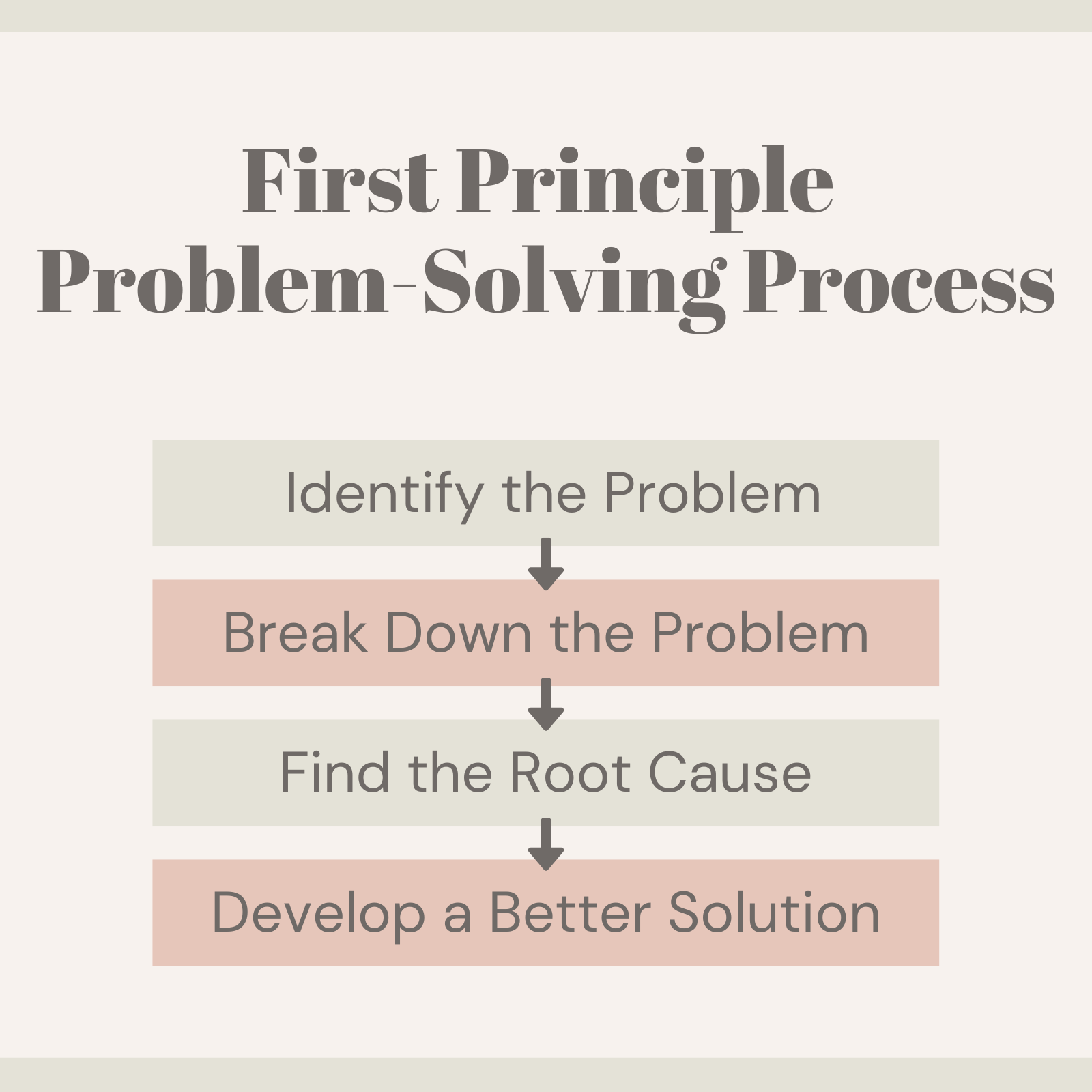

For an application to become a solution, you must first understand the underlying cause for the problem in order to fix it. That’s why I’m a big believer in the “First Principle” concept - a method of analysis in which you break down a problem to its basic components to determine what’s really essential.

Now in my experience it’s hard to apply the First Principle concept if you sit around in an office and don’t go into the field. You have to go where the application will be used in order to understand the pain points that the user experiences.

An example of this faulty approach to product development in the last-mile delivery industry are the camera systems that are often used in package-transport vehicles. The camera-based, artificial-intelligence (AI) powered, automatic lighting control system was intended to illuminate the contents of the load space for a driver to identify packages. The system is suppose to turn on the lights when the driver walks into the cargo hold and automatically turn off the lights when the driver leaves, thereby saving energy consumption.

AI Camera Cannot Detect Driver in Dark Environment

GHE Solution: Wireless Light Tags for Reliable Package Identification

Although this camera-AI-based control system does work perfectly during the day, it doesn’t do so at night. That’s because the camera can’t capture the driver’s behavior and movements when entering the load space in the dark. The result is that the automatic control fails. So, what does the driver do? At night, he or she turns on a mobile phone light to find the package in the cargo area.

Ineffective applications are what happens when engineers don’t have any real-world experience or knowledge. Had the design engineers gone on the road with a delivery driver, they would have learned that an expensive camera systems using complex AI algorithms wasn’t the answer. Instead they might have realized that the solution is the use of low-cost pyroelectric passive infrared detectors. This technology can more accurately detect the driver's behavior of entering the vehicle compartment during both the day and night.

If we had sat around in an office, we never would have been able to develop the GHE solution that helps drivers find packages for last-mile delivery. You don’t understand the pain points and needs of drivers unless you spend time driving around with them on city streets or rural roads.

Having worked as a delivery driver, I saw the need firsthand to develop a solution to increase delivery efficiency while making the work safer and easier. The GHE solution does just that. It uses wireless light tags on packages to provide visual and sound cues to direct a driver to the package location in a cargo compartment.

Technological innovation won’t make an application an effective solution for a problem if the invention does not fix the underlying pain point behind the need. It’s a mantra we embrace here at LotWork (https://www.lotworkiot.com/) & GHE(https://www.ghelmd.com/) in developing our solutions for industry.