From Data to Decisions: Turning Warehouse Activity into Insight

Gent +Ivziku • December 3, 2025

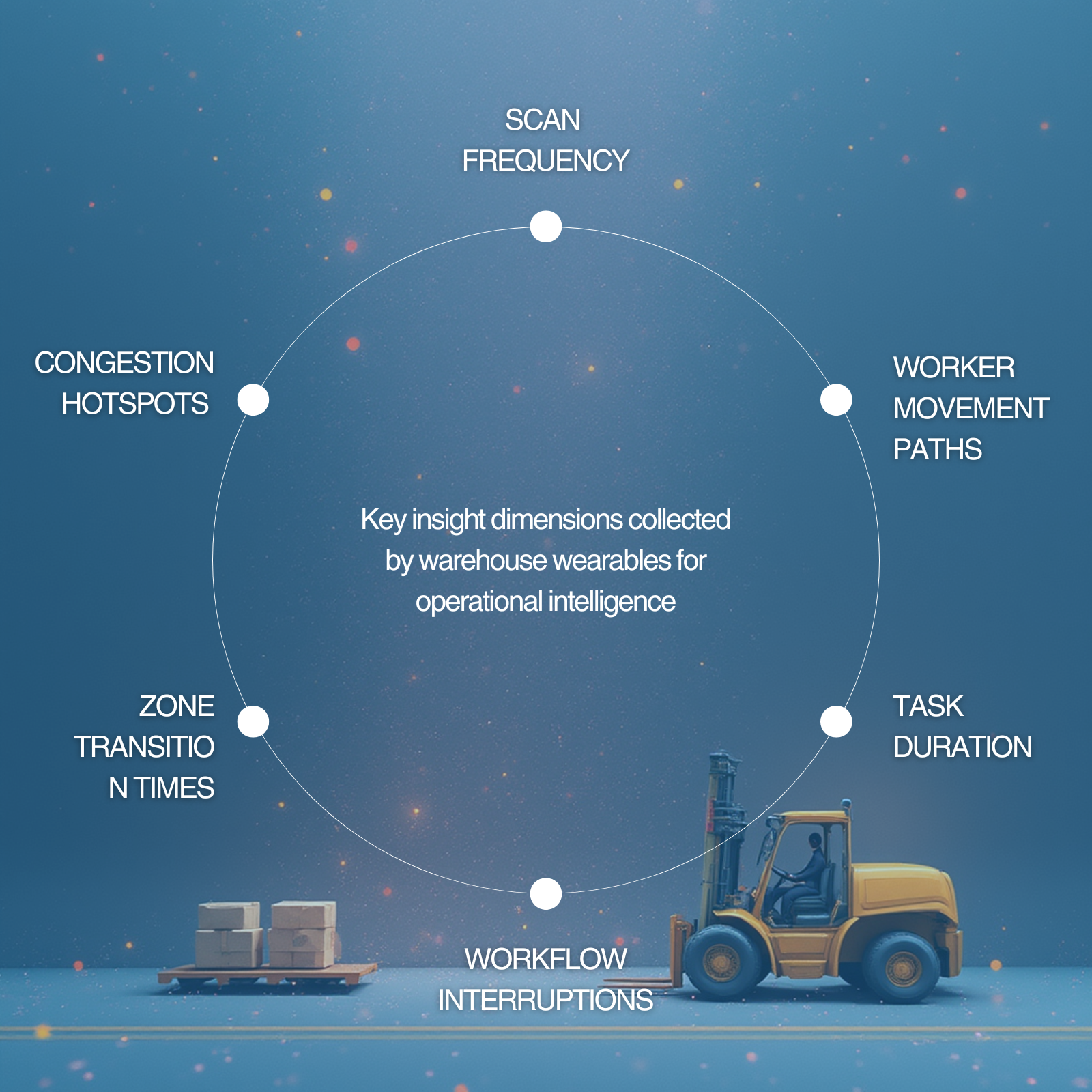

In modern warehousing, every movement matters. The challenge is no longer whether operations generate data, it is whether leaders can turn that data into clear, actionable decisions. With incr easing pressure for faster fulfillment, tighter margins, and greater operational visibility, warehouses must move beyond reactive management and into intelligent, data driven control. At Lotwork, this is exactly where our wearable technology makes the difference. By capturing real time motion patterns and scan activity, our devices unlock a level of visibility that goes far beyond traditional barcode scanners or handheld terminals.

This information is then processed through our advanced analytics engine, converting raw operational signals into AI insight that managers can immediately act on. Instead of relying on delayed reports or surface-level KPIs, decision makers gain access to real time visibility into productivity trends, congestion zones, inefficiencies, and performance variations. They can see where time is being lost, where processes break down, and where improvements will have the most measurable impact.

The true power lies in what these insights enable. With accurate, data backed understanding of warehouse activity, leaders can optimize pick paths to reduce unnecessary travel, rebalance labor to match demand patterns, enhance training programs based on real performance gaps, and strategically introduce automation where it delivers maximum return. Teams, shifts, and zones can be compared in detail, allowing best practices to be identified and scaled across the operation. This is warehouse optimization rooted in evidence, not assumption.

Beyond efficiency, this level of visibility also supports smarter forecasting, improved workforce planning, and stronger compliance monitoring. Managers can proactively address fatigue risks, reduce congestion related safety hazards, and create a more structured and predictable operational environment. The result is not just faster performance, but more consistent, sustainable productivity that supports long term growth.

As warehouses evolve to meet the demands of e-commerce and high speed logistics, the ability to understand exactly what is happening on the floor in real time becomes essential. Lotwork wearables bridge the gap between physical activity and digital intelligence, empowering organizations with the clarity needed to make confident decisions. From motion to insight and from insight to action, we transform everyday warehouse activity into strategic intelligence that drives smarter decisions, higher efficiency, and stronger operational control.

About the Author

Gent Ivziku

Client Success Manager, Lotwork

Gent is a Client Success Manager at Lotwork, helping teams find smarter, faster ways to get work done using wearable tech and hands-free scanning. He’s passionate about simplifying warehouse and logistics workflows and enjoys working closely with customers to find the right fit for their needs. Outside of work, he’s a big fan of soccer and loves diving into great movies and TV shows whenever he gets the chance.