Maximizing Efficiency - Streamlining Packing with

Ergonomic Plug&Play Scanning Solution

In the fast-paced world of fulfillment centers, efficiency and speed in packing play critical roles. The choice of scanning devices profoundly influences these factors. Let's delve into a comparative analysis between traditional handheld scanners or PDAs and our revolutionary HYCO Ring Scanner, focusing on how our product outperforms conventional solutions.

The status quo: traditional handheld and stationary scanners

Challenge 1: Handheld scanner occupying a Hand and Increased Labor Intensity

Traditional handheld scanners occupy a worker's hand, necessitating frequent picking up and putting down during the scanning process. This repetitive action increases labor intensity and decreases overall efficiency.

Challenge 2: Stationary Scanners and the Effort of Lifting Items

Another common approach is to fix scanners on the desk's top, requiring workers to lift items for scanning. This approach is particularly effort-intensive, especially for heavy or large items, as it involves lifting the item to the scanner for every scan.

The Solution:

Our innovative HYCO Ring Scanner offers a distinct advantage over these traditional scanning methods

Solution 1: Hands-Free Operation - Optimal Workflow

Traditional scanners may require a worker to pick them up, aim & scan the barcode, and then put them back down. This process can take up to 5 seconds and occupies a hand, hindering efficiency. Conversely, our ring scanner is designed to be worn on a finger, ensuring hands-free operation. This ergonomic design allows workers to work seamlessly and efficiently, saving both time and effort. Moreover, with hands-free scanning, our ring scanner guarantees the safety of items being handled, preventing accidental drops or mishandling during the scanning process.

Solution 2: Scan Without Lifting - Efficiency at its Best

Unlike fixed scanners that require lifting items for scanning, our ring scanner, worn comfortably as a ring, allows for scanning without the need to lift the items. This eliminates the 2 seconds time cost associated with lifting and provides a significant time-saving advantage. Additionally, by avoiding the need to lift potentially heavy or awkwardly shaped items, our ring scanner effectively prevents potential human injuries, prioritizing both efficiency and worker well-being.

Realizing significant cost savings

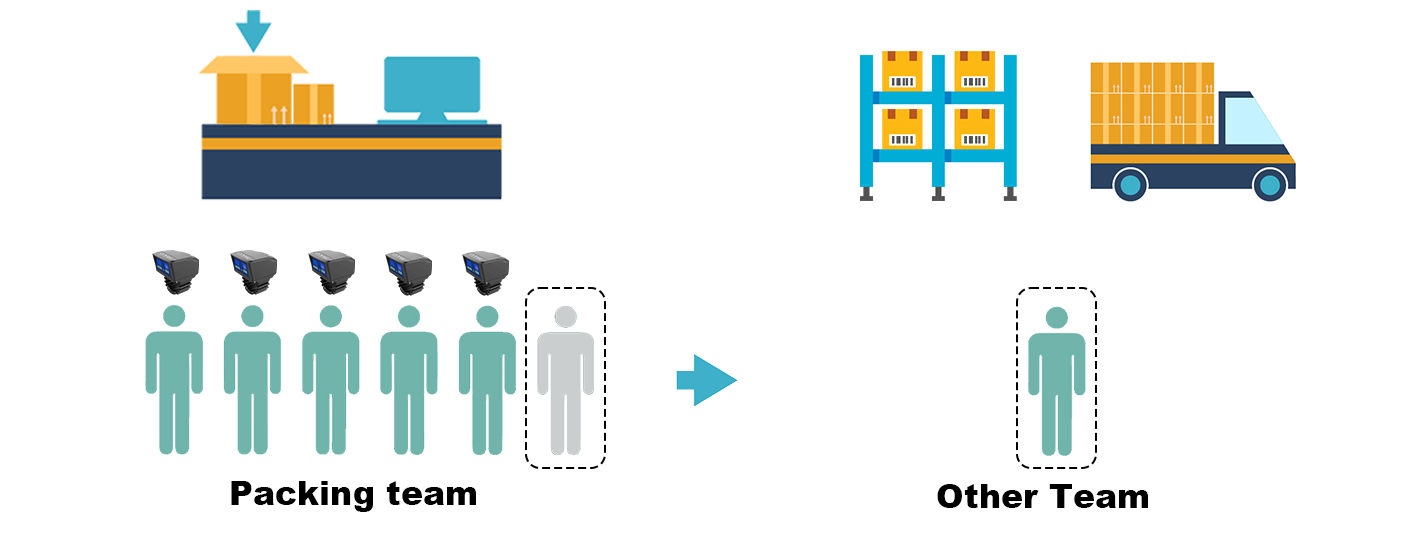

In the realm of fulfillment centers, managing labor costs is paramount. The cost of hiring, training, and maintaining a workforce can quickly accumulate, especially when considering attrition rates and the time it takes for new hires to reach optimal productivity levels. For instance, new hires can take up to 4 weeks to match the productivity of their predecessors, leading to the need for additional workers during this transition period. This not only incurs extra costs but can also increase errors, causing a ripple effect of return and re-shipment costs, ultimately impacting employee morale and overall productivity.

Our product emerges as a potent solution. It can save approximately 50% of time per item compared to traditional scanning methods. This significant time saving translates directly into labor cost savings. For example, in a team of six packers, the efficiency gained could enable the workload of five packers, thereby reducing the cost of employing one packer. Considering the average annual labor cost for a packer is approximately $50,000, this efficiency gain could lead to an annual cost saving of $50,000.

Moreover, the HYCO Ring Scanner offers a seamless integration process. It's plug and play, requiring no elaborate installation. Management can witness a rapid return on investment; in this scenario, achieving a 1-month ROI of approximately 150%. Looking ahead, the potential 1-year ROI is remarkable, reaching up to 1700%.

To put it in perspective, let's consider attrition. If, on average, 100 warehouse associates are lost each year, reducing this number by 15% through the implementation of our efficient ring scanner could result in a

cost saving of $112,500. These numbers not only reflect tangible cost savings but also embody the intangible benefits of enhanced employee morale and an improved customer experience.

The Hyco ring scanner - a pioneering solution

In the dynamic world of fulfillment centers, efficiency and cost-effectiveness are paramount. Our HYCO Ring Scanner stands as a pioneer, offering a simple yet powerful solution to streamline the packing process. By saving time, reducing labor intensity, and cutting down operational costs, it propels fulfillment centers into a new era of productivity and profitability.

References:

https://www.amwarelogistics.com/fulfillment-costs-reduction