The Last 10 Feet Problem: Fixing the Final Step in Fulfillment

Abdul Qazi • December 10, 2025

In every warehouse, distribution center, and pharmacy operation, the hardest part of the job is often the final step. Fast conveyors, strong WMS systems, and optimized storage layouts can move products efficiently, but when a worker approaches the last 10 feet of the pick location, accuracy becomes vulnerable. This moment is where most fulfillment errors occur. Workers may pick from the wrong bin, miss an expiration date, or misread a label. These last meter mistakes lead to returns, inventory inconsistencies, compliance issues, and lost customer trust.

The industry calls this challenge the Last 10 Feet Problem, and solving it has become a priority for companies that want both speed and precision. Lotwork addresses this issue directly through advanced pick to light technology and intelligent guidance systems that deliver accuracy exactly where it matters most.

Why the Last 10 Feet Matter

The closer a worker gets to an item, the more manual judgment is required. Even experienced pickers can struggle during peak hours, complex batch picking, or when handling products with similar packaging. In pharmacies and controlled environments, the margin for error is even smaller due to FEFO requirements, safety standards, and regulatory checks.

Common causes of last meter errors include picking from the wrong bin in high density shelving, confusion between similar SKUs, misreading labels or expiration dates, time pressure during surge periods, and inconsistent paper based or voice based instructions. Even a small slip at this stage has outsized consequences. That is why more warehouses and pharmacies are moving toward visual guidance systems that remove guesswork altogether.

How Lotwork Solves the Last 10 Feet Problem

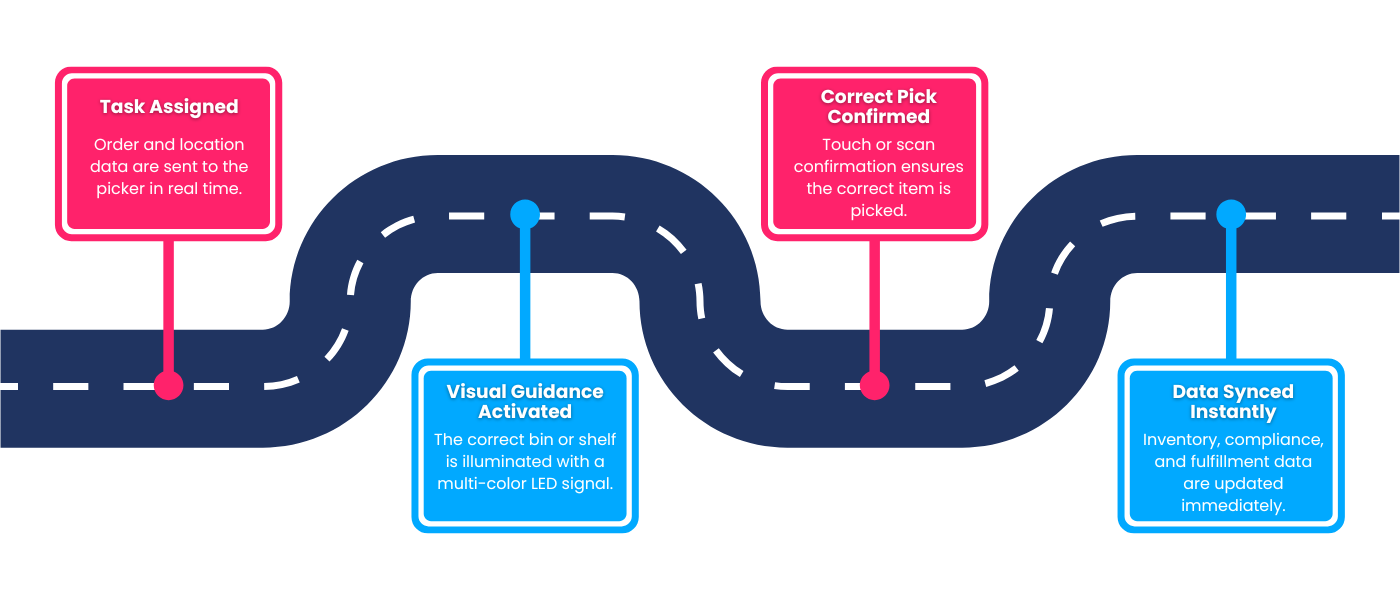

Lotwork's Light Tag and Pick to Light solutions are built specifically to guide workers through the final step of fulfillment with precision, clarity, and repeatable accuracy. These systems combine long lasting wireless tags, multi color LED indicators, audio prompts, and real time system updates to eliminate confusion during the last meter.

Each Light Tag illuminates the exact bin or shelf the worker must pick from. The LED signal removes guesswork and ensures the correct touch point every time. Workers receive immediate confirmation when they touch the right location. This instant feedback cuts errors and builds confidence even during busy hours.

Lotwork tags operate for extended periods without charging, supporting uninterrupted workflows and reducing maintenance demands. With the LightPickRx workflow and FEFO Manager, pharmacy teams are guided to the correct medication and the correct expiration date. This supports compliance, reduces waste, and ensures patient safety. Tags can be placed on shelves, totes, carts, and mobile racks without requiring changes to warehouse layout, supporting dynamic picking environments and high mix operations.

Where Last Meter Accuracy Matters Most

The Last 10 Feet Problem affects multiple industries, and Lotwork solutions are designed to support each one. In warehouse fulfillment, workers move faster and with fewer errors when visual cues guide them directly to the correct bin. This increases item accuracy and speeds up onboarding for new employees. In pharmacy operations, LightPickRx improves accuracy for prescription fulfillment, compounding rooms, and medication storage by ensuring items are picked according to FEFO standards. In manufacturing and kitting, Light Tags guide workers to precise components, reducing the risk of line disruptions and rework.

The Future of Accurate Fulfillment

The final step of the picking process is often the one with the highest stakes. Lotwork solves the Last 10 Feet Problem by delivering precise, visual, and reliable guidance where workers need it most. By integrating Light Tags, pick to light workflows, and intelligent pharmacy tools like FEFO Manager and LightPickRx, warehouses and pharmacies gain higher accuracy, fewer errors, and smoother operations across every shift.

Ready to transform your operations?

Get in touch with our team:

- Email: support@lotworkiot.com

- Phone: +1 (800) 921 3788

Book a Demo: Visit www.lotworkiot.com to see the technology in action

" Hi, I’m Abdul Qazi, Customer Service Manager at Lotwork. I work closely with companies across industries to help them improve speed, efficiency, and accuracy through automation solutions like wearable scanners, pick to light systems, and smart warehousing tools.I have spent years helping businesses find the right solutions to meet their needs. I enjoy connecting with people, understanding their challenges, and working together to solve problems that make a real impact.

This blog is here to help you better understand our products and how they can support your operations. Whether you are exploring automation for the first time or looking to upgrade your systems, I hope you find the insights here useful and easy to apply.

"