The True Cost of Light Tag Systems: Why Smart Warehouses Are Making the Switch

Abdul Qazi • July 29, 2025

Hardware That Actually Works in Real Warehouses

L102 Rechargeable Light Tag

The workhorse of warehouse operations, featuring:

- Customizable RGB lighting for instant visual guidance

- 30 month battery life with convenient recharging

- Audible confirmation to eliminate pick uncertainty

- Lightweight clip on design that workers actually want to use

Smart Color Coding System options:

- 🔴 Red: Urgent/rush orders

- 🟢 Green: Standard picks

- 🔵 Blue: Restocking tasks

- 🟡 Yellow: Quality control required

Smart Color Coding System (Collaborative Roles)

- 🔴 Picker 1

- 🟢 Picker 2

- 🔵 Picker 3

- 🟡 Picker 4

This intuitive system prevents costly errors before they happen.

The Numbers Don't Lie: ROI Breakdown

| Performance Metric | Manual Picking | With Lotwork Light Tags | Improvement |

|---|---|---|---|

| Picking Speed | Limited by search time | Guided by visual/audio cues | +20% faster |

| Pick Accuracy | Error-prone | Light-guided precision | 35% fewer errors |

| Training Time | 2-3 weeks | 2-3 days | 75% reduction |

| Labor Efficiency | Fatigue impacts performance | Optimized workflow | Consistent output |

| Sustainability | Disposable solutions | Rechargeable technology | 90% less waste |

Average Payback Period: 4-6 months across all industries

Real World L102 Applications

Fulfillment Centers: Fast and accurate pick to light operations. In high volume eCommerce warehouses, workers use L102 tags to instantly identify the correct bin, cutting pick times and eliminating errors during peak sales.

Pharmacies: Prescription pickup zones for error-free handoffs. Busy pharmacies use L102 tags to light up when orders are ready, guiding staff to the right medication and ensuring correct customer deliveries.

Tool Management: Light guided tool check-in/check-out stations. In manufacturing plants, technicians use L102s to quickly locate tools and confirm returns, reducing lost equipment and simplifying audits.

Software That Integrates, Not Complicates

Lotwork connects seamlessly with your existing WMS or operates independently

Implementation That Actually Works

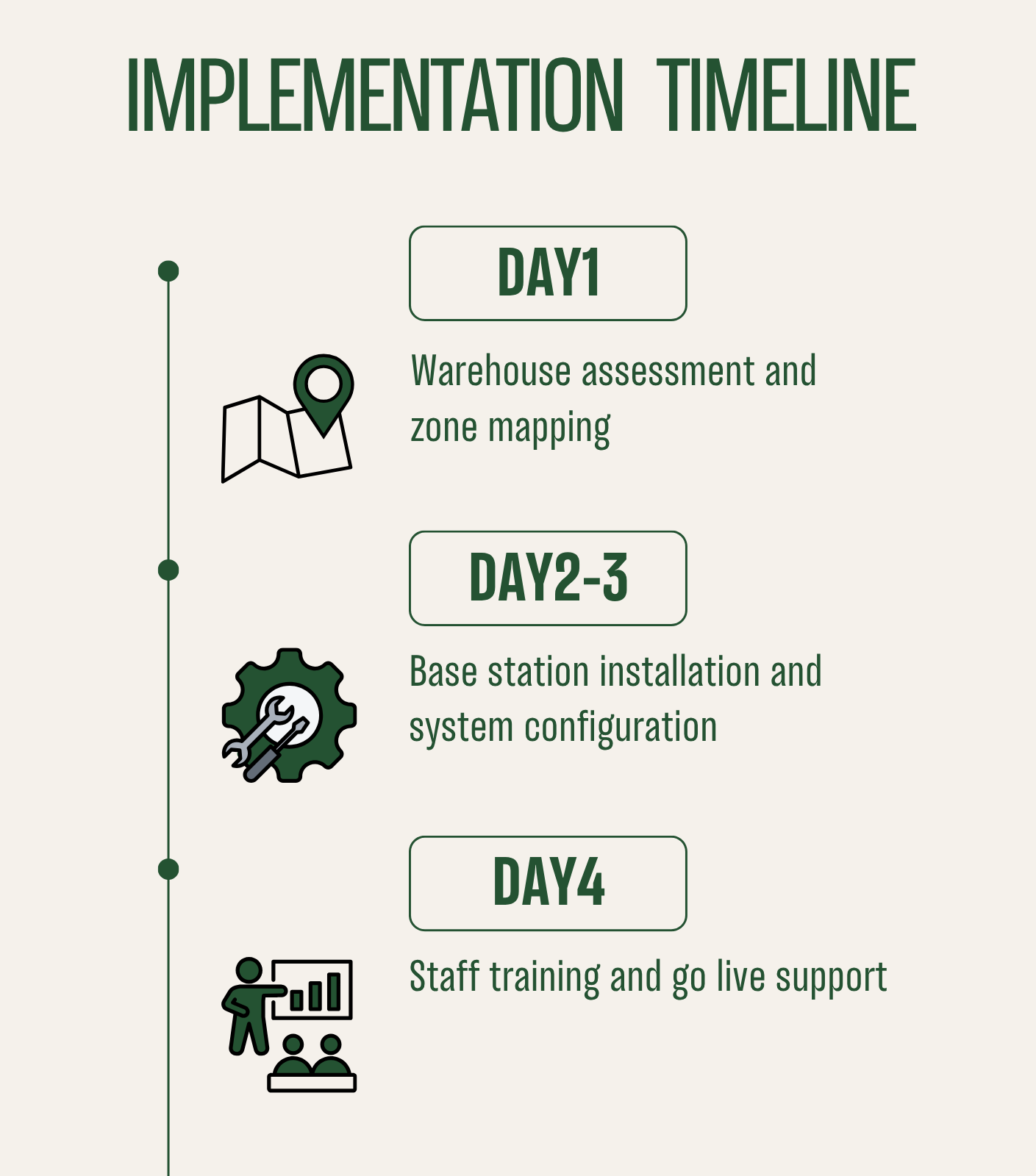

Unlike complex warehouse automation projects, Lotwork deployment is straightforward:

- Day 1: Warehouse assessment and zone mapping

- Days 2-3: Base station installation and system configuration

- Day 3: Staff training and go live support

Most facilities are fully operational within 3 days, with teams reaching full proficiency in just 48 hours.

Built for the Long Haul

Lotwork's industrial-grade construction delivers:

- 3+ year operational lifespan with proper maintenance

- Remote support keeps systems optimized

- 90% reduction in battery waste compared to disposable alternatives

- Future-proof scalability as your operation grows

The Investment That Pays for Itself

While light tag systems require upfront investment, Lotwork delivers:

- Immediate productivity gains from day one

- Rapid ROI typically under 6 months

- Scalable solution that grows with your business

- Sustainable operations with minimal environmental impact

- Future-proof technology backed by ongoing support

Ready to transform your warehouse operations?

Contact Our Team

Email: info@lotworkiot.com

Phone: +1 (800) 921-3788

" Hi, I’m Abdul Qazi, Customer Service Manager at Lotwork. I work closely with companies across industries to help them improve speed, efficiency, and accuracy through automation solutions like wearable scanners, pick to light systems, and smart warehousing tools.I have spent years helping businesses find the right solutions to meet their needs. I enjoy connecting with people, understanding their challenges, and working together to solve problems that make a real impact.

This blog is here to help you better understand our products and how they can support your operations. Whether you are exploring automation for the first time or looking to upgrade your systems, I hope you find the insights here useful and easy to apply.

"