The payoff goes well beyond dollars saved. Precision tech lifts team confidence, reduces stress on the floor, and strengthens trust with customers. Fewer mistakes mean fewer frustrated calls, fewer returns, and fewer hours wasted on corrections. Managers benefit as well, gaining more accurate data from the floor to make better decisions on staffing, inventory, and fulfillment strategies. Over time, this accuracy compounds into smoother operations, higher throughput, and greater resilience against unexpected spikes in demand.

The financial returns are obvious, but the cultural impact, knowing your tools will not fail you, may be even more valuable. Workers can trust their equipment, managers can rely on consistent performance, and customers can count on getting the right product every time. These are the details that separate a good operation from a great one.

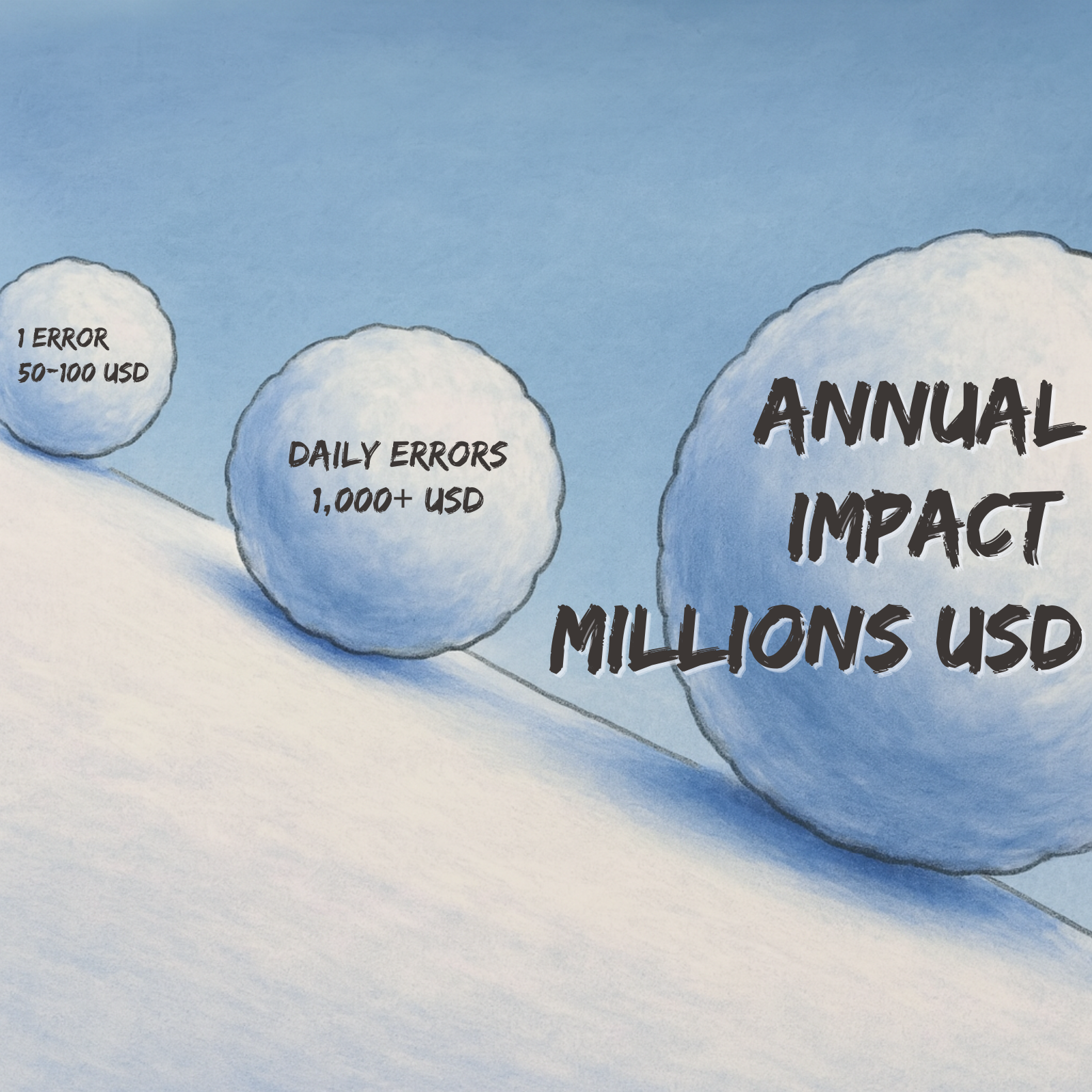

In the end, precision is not just about eliminating errors. It is about building an operation that can scale, perform, and compete without being dragged down by avoidable mistakes. That is why investing in accuracy pays for itself many times over, delivering both immediate savings and long term strength.