Micro Innovations Part II

August 15, 2024

How Labeling Efficiency Was Improved For A Major Chinese Logistics Company

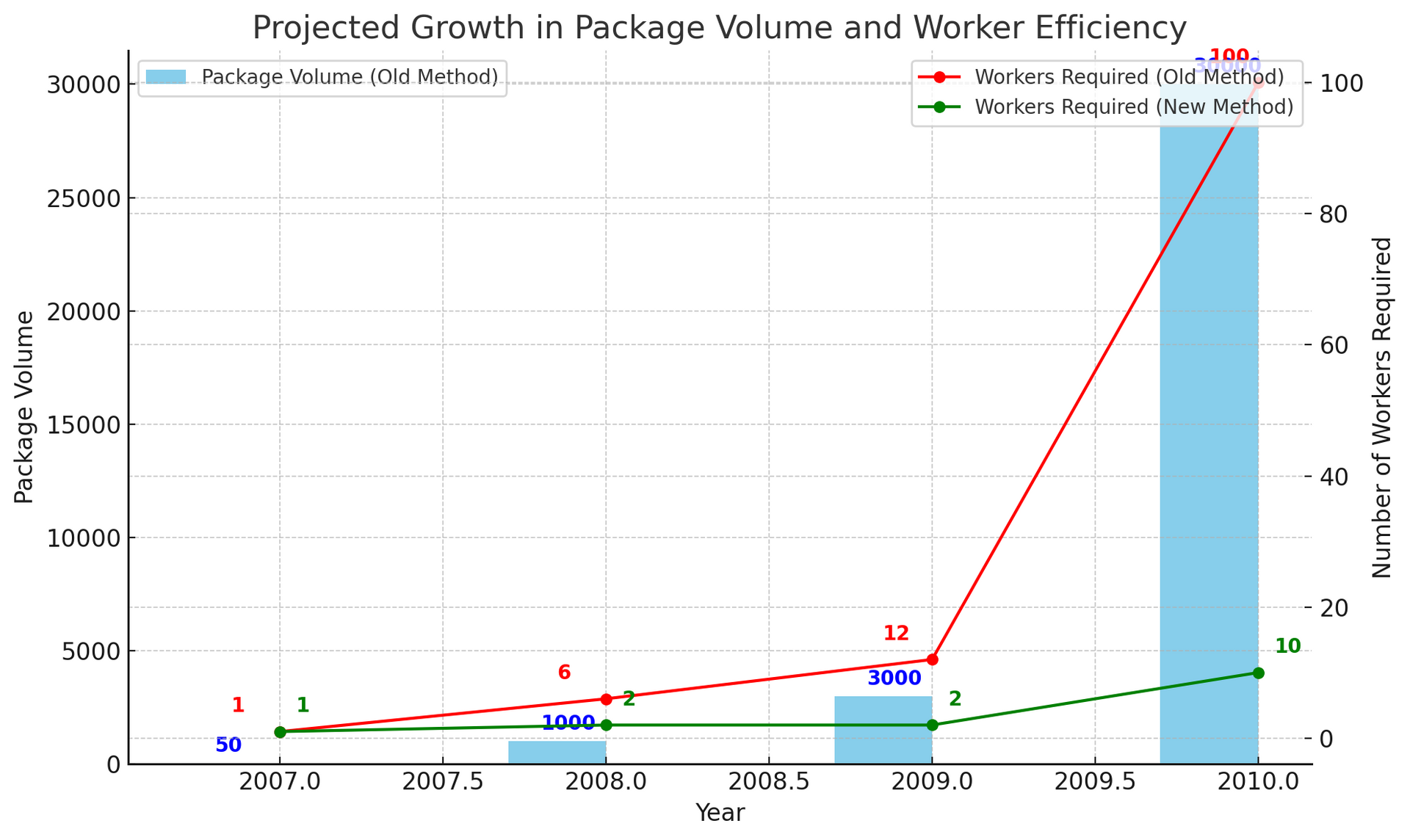

In April 2009 I was working as a consultant and looking into the e-commerce customer service for a major Chinese express logistics company when I was taken aback by what the business was doing. It had workers manually attaching 3,000 printed courier labels to packages each day. That task required 12 employees to work overtime for more than ten hours.

When I met with the husband and wife who co-owned the business discuss that practice, I posed this question: What would you do if your daily shipments increased to 30,000 next year?

They responded that their company would expand the work space and hire more workers, likely a hundred more employees if they could find them.

I pointed out that even a thousand workers would struggle to process 30,000 packages a day with the current system. Then I asked them how many packages their company had handled when it first started.

The owners replied when the business was launched in 2007, it handled just a few dozen packages, an amount that was easily managed by one worker in a few hours. As the business grew and volumes increased, they maintained that same approach to applying package labels.

I proposed that the company speed up the labeling process by modifying the workflow and taking advantage of automatic package identification. Instead of printing the labels first and then finding packages to attach them to, the workers should scan the package information first, print the corresponding label on the spot, attach it, and then scan it into the system.

Making this change would eliminate the extremely difficult task of matching thousands of labels to thousands of packages. If the change was made, I said, two workers in two hours could manage three thousand packages. Furthermore, I told them, if they continued with the current method, that approach would become exponentially harder as the number of packages increased and ultimately be unsustainable.

When the owners saw the promised results, they invited me to give multiple lectures on efficiency, micro innovation, and scientific methods for process optimization at their executive meetings and company-wide conferences. Over the following years, I gave dozens of lectures on these topics at almost all large express logistics companies in China, sparking a wave of innovation and process optimization across the industry. I believe my work contributed to the rapid advancement of China's express logistics industry, as it went in a just a few years from merely emulating Western counterparts to leading the way in timeliness, cost, and loss rates.

Now that I’ve come to the United States, I hope to extend these experiences, micro innovation, and scientific methodologies to North America. My goal is to improve the safety and comfort of express service workers while doubling their efficiency.